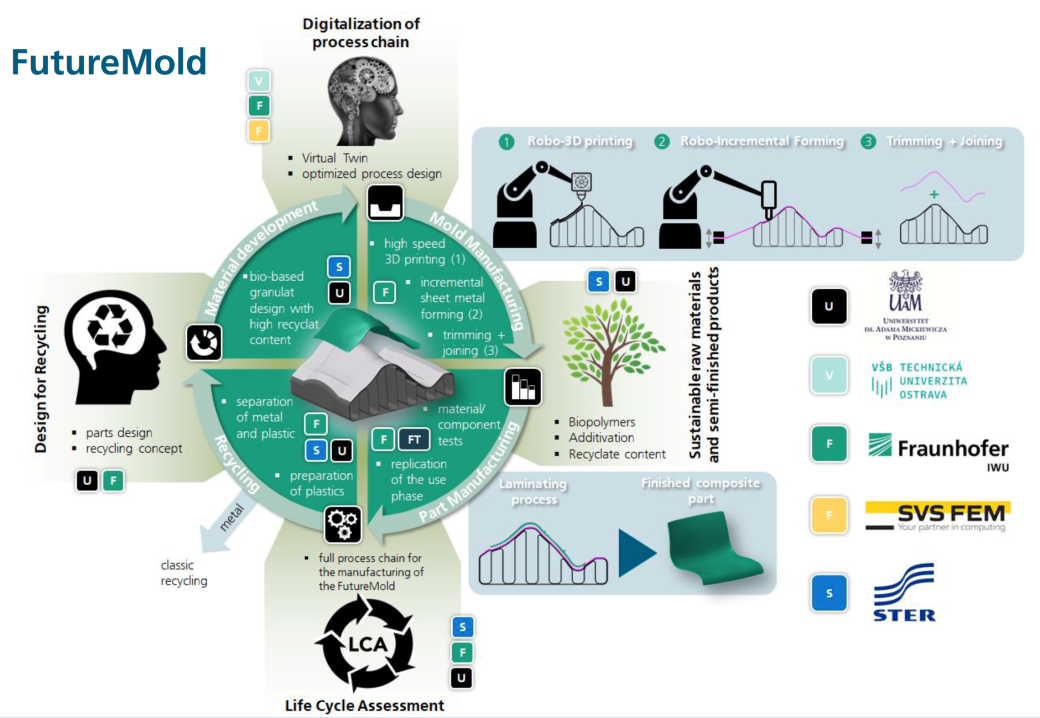

The main objective of the FutureMold project is to develop a novel, cost- and material-efficient hybrid method for manufacturing molds for lightweight fibre-reinforced plastic (FRP) components by combining 3D printing and incremental sheet metal forming (ISF). The base body of the mold is produced by 3D printing a biopolymer, onto which a metal layer is subsequently robotically applied using the ISF method. This hybrid manufacturing process combines rapid additive manufacturing with flexible sheet forming, which minimises material consumption, shortens production time, and simultaneously increases the service life of the molds. A key element of the approach is a detachable joint between the polymer core and the metal layer, which facilitates recycling and secondary material use.

New innovative molds promise to reduce production-related CO2 emissions and cost contribution to less than 5 % compared to the current 25 %. The Future Mold project can help significantly reduce the carbon footprint and production costs of machinery industries that use lightweight fiber-reinforced plastic (FRP) components, such as rail, marine, aerospace, and agricultural.